Sie sind nicht angemeldet.

.

.Dieser Beitrag wurde bereits 1 mal editiert, zuletzt von »kevin22« (24. März 2009, 00:02)

Nige

Nige

Dieser Beitrag wurde bereits 1 mal editiert, zuletzt von »okdoky« (24. März 2009, 21:42)

Zitat

Original von okdoky

Hi Alex

Measuring the alumium foil with a micrometer puts the thickness at between 0.05 and 0.07 mm thick.

...

...

Zitat

I save all the carry out and roasting trays that are made up of aluminium foil and save a fortune on buying plastic sheet of the same thickness.

aside from the fact that it is free and sometimes only needs a quick trip through the dish washer before use, I find that I can make complicated shapes with bending and pressing just like a metal fabricator does with car panels.

we´ll only have to get through our world with open eyes

we´ll only have to get through our world with open eyes  .

.

Zitat

I am still learning but there is a friend on another site, Ian Sadler, who uses toothpics to burnish the foil into shape around plastic parts from kits or where ever he finds a patern or shape on everyday objects and uses the foil to replace overly thick moulded parts on kits.

I would love to have the skill he has with the foil.

.

.

Zitat

And as you say, I do need to get on with the models if I am to get them on show in April. So must get the finger out my a** and get working.

Wise words -

Wise words -  let´s go back to modeling then

let´s go back to modeling then

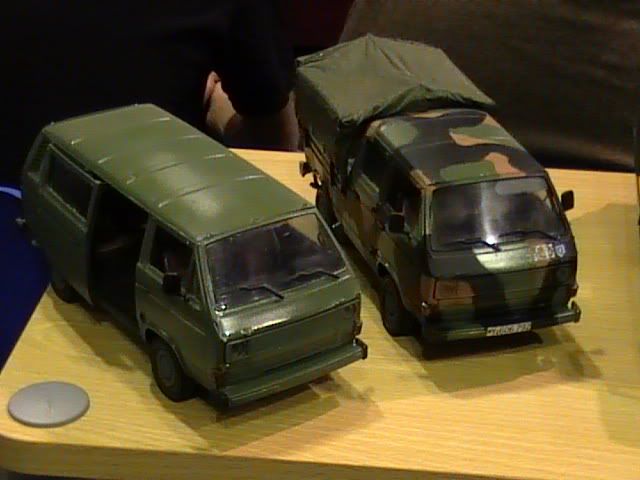

Am much happier with the look

Am much happier with the look

Zitat

Original von okdoky

.... [snip]

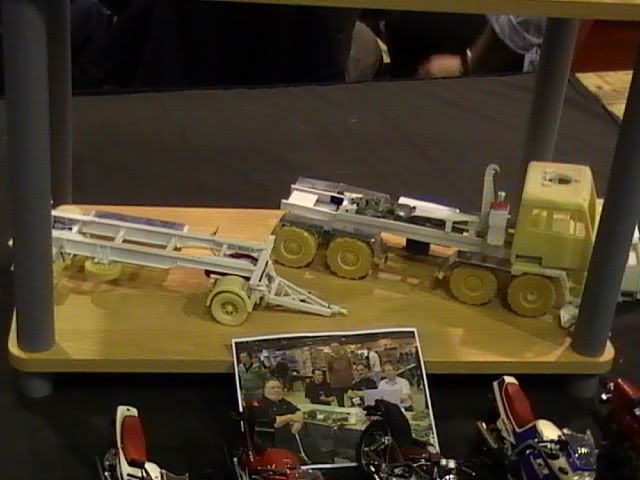

Looks like I will have these at Perth as in progress models only. Never mind I can be doing things to them while I am sitting at the table. [snip]

Nige

Thanks for the support all

Thanks for the support all

Zitat

Original von dulti500

Hallo Nige

nice work i can see. I like it. very good.

I hope, i can see it in germany sometime

Greetings Dulti

(my englich is not good!!!!)

Forensoftware: Burning Board®, entwickelt von WoltLab® GmbH